Quality System

The Quality Management System gives the organization a focal point for promoting best practice and continuous improvement in accordance with Quality Policy of Hussain Group. The adoption of the quality control and management system is a strategic decision of Hussain Group. Varying needs, particular objectives of quality, the product provided and the processes employed influences the design and implementation of our quality control system. Under the ISO Standards, we promote the adoption of a process approach when developing and improving the effectiveness of a quality management system, in order to enhance the customer satisfaction by meeting customer requirement. The process approach let us to understand and meeting requirements, obtaining result of process performance and effectiveness and improvement of different processes based on objective measurements.

Under the ISO Standards, we promote the adoption of a process approach when developing and improving the effectiveness of a quality management system, in order to enhance the customer satisfaction by meeting customer requirement. The process approach let us to understand and meeting requirements, obtaining result of process performance and effectiveness and improvement of different processes based on objective measurements.

For highest level of quality, Hussain Group emphasize on corrective and preventative action plan. To control the unexpected consequences and errors in the system, the centralized corrective action plan is taken and the concerned personnel immediately take the corrective action. The IT Department maintains the computerized database to keep records

The need of our spinning infrastructure is to produce yarn with quality meeting 100% to the specifications of the customers. The yarn should be engineered according to the desire specifications under International Standards of Quality. This can be achieved with intelligent quality testing and management systems, which monitor quality continuously and alert the personnel of department of ISO and production, whenever exceptions are encountered. This would reduce unnecessary loss of material due to the quick corrective response.

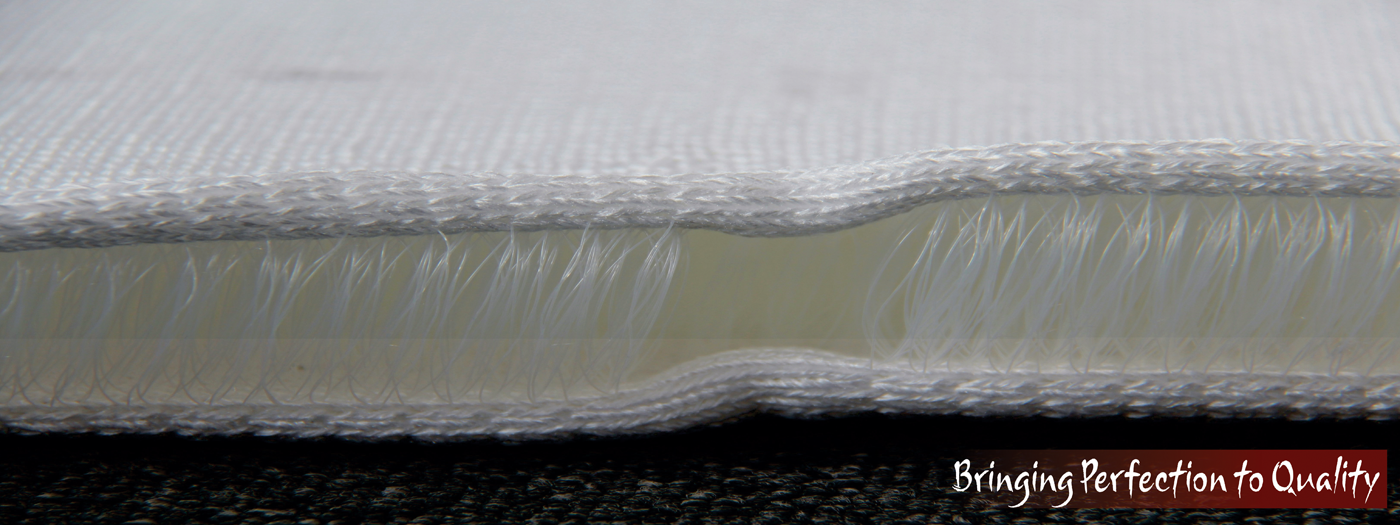

Weaving Profile

HML 4 – (WEAVING UNIT)

Looking ahead although we have an impressive history of growth, our focus is always on the future and not to rest on our laurels. We shall continue to meet the consistency and quality by closely monitoring the vital signs of our business along with new products. Hussain Group is proud of where we’ve been, and we are more excited about where we are going.

Hussain weaving is famous nationally and internationally due to his good quality. With Grace of Allah Hussain Mills has spreaded his product in almost all famous textile countries and we feel proud mentioned name Germany, Holland, Italy, Portugal, France, China, Hong Kong, India, Sri Lanka, Turkey, and Unites States of America.

We are specialized in articles making:

Woven Grey Fabric, Dobby, Yarn Dyed with counts up to 600 threads for Sheeting, Apparel, Suiting and Home furnishing accessories with the elegance of Stretches, Bi-stretches, Reverse satins, Satins, Twills, Drills, Percale' B.F.C., Rib Stop and Herring bone & non Dobby Designing Items. Batcher motions are also used for specific piece length requirement.

HML-4 (WEAVING UNIT)

We believe in research and experiments; our manufacturing unit use state-of-the-art looms and latest weaving techniques to achieve consistency and excellent quality in the fabrics.

LOOMS SETUP

Model: Tsudakumu ZAX – 9100 (Professional)

| Loom Widths | No. of Looms | Options | No. of Shafts on looms |

| 190 cm / 75 inch | 55 | Leno | 8 – 10 Shafts |

| 210 cm / 83 inch | 20 | Leno | 10 Shafts and 4 – 6 Colors |

| 230 cm / 83 inch | 6 | Leno / Tuck in / Centre Leno | Dobby / 4 Colors |

| 280 cm / 110 inch | 8 | Leno / Tuck in | 10 Shafts |

| 340 cm / 134 inch | 41 | Leno / Tuck in / Centre Leno | 10 Shafts |

| Total No. Of Looms | 130 |

Monthly capacity is approximate 1.800 million meters.

Warping (2 Machines

1) Benninger

Model: Ben Direct 1000

Creel Capacity: 1224 & 1088

2) Sectional Warping (From HI FANG)

With creel capacity 764 (Both for Narrow and Wider widths up to 134"

Sizing

Benninger>

Model: Ben sizetec ZB28 KVD/KVD CT4/4/6 BB

Creel Capacity: 28 warp beams

Size box

No. of size boxes = 2

Type = Double dip & Pre wetting

Working width = 2400mm

Head Stock

Max. Working width between the flanger = 4000mm

Max. No of ends possible to run in sizing = 34272

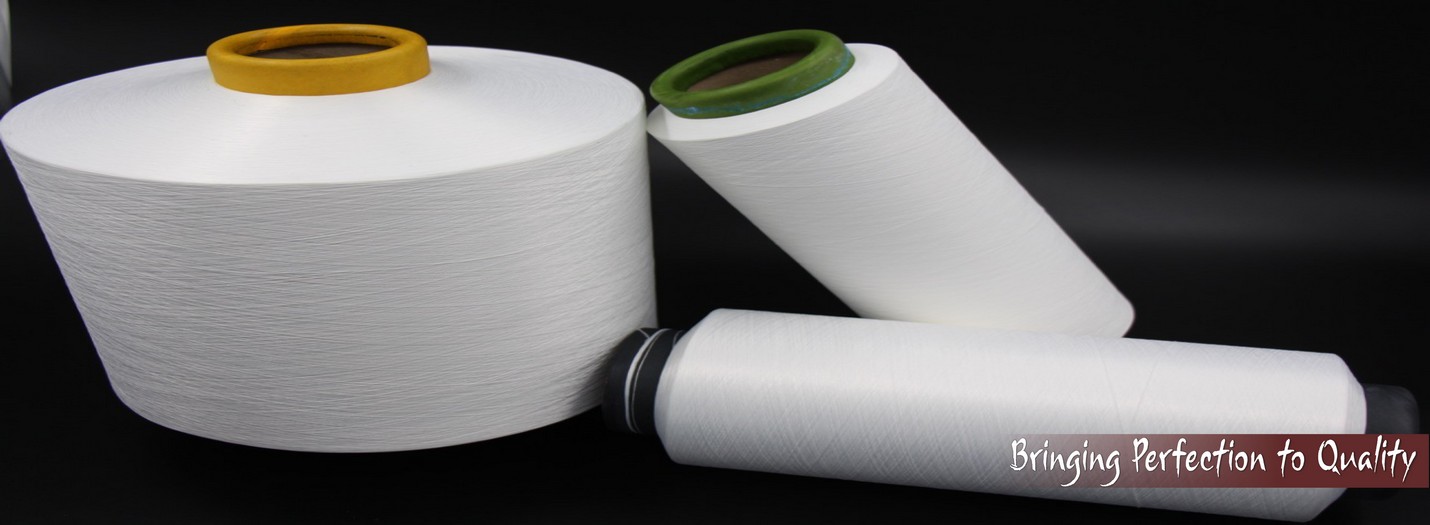

Spinning Profile

What is Spinning?

The Spinning is a technological system in which twist is inserted to the fibers and yarn is produced. The spinning process includes many processes which transforms the bales of raw cotton into a yarn ready for weaving. The term "spinning" can refer to the whole activity or just to the final process of making the yarn. The raw cotton arrives in the form of large bales. These are broken open and a worker feeds the cotton into a machine called a "breaker" which gets rid of some of the dirt. The cotton may not be consistent in quality from bale to bale therefore samples are taken before getting bales in best quality.

Following processes are involved in manufacturing of yarn.

Mixing

Mixing of cotton brought to make a uniform blend in order to make a uniform yarn with high quality parameter in order to avoid any shade problem. For this purpose, the number of bales are mixed to get uniform results. Raw cotton is purchased from best cotton growing areas of country and also cotton bales are imported from foreign countries. For stocking and mixing, sandwich-mixing technique is used.

Back Process.

Back process of yarn manufacturing process is contributed by following sections.

a. Blow Room Section

b. Carding Section

c. Drawing Section

d. Combing Section

e. Simplex (Roving formation)

a) Blow Room

In the Blow room section cotton is opened and cleaned through the following machines.

1. Auto Bale Plucker

2. Single Roller Cleaner Machine "B11"

3. Chute Feed System

4. Loptex (Contamination Control System)

b) Carding.

In this section cotton is opened cleaned and formed slivers of particular thickness. Each unit of Hussain Group has one of the best carding machines in the world. Following machines are used in this process

1. Crosrol MK 5D

2. Trutzchler DK 903

c) Drawing Section

In the Drawing section sliver is doubled, blended and drafted to parallel all fiber and to control and straighten the hooks present in cotton to form a uniform & even sliver for production of high quality yarn of very low CV%.

Hussain Group has following machine which are used in this process.

1) DX7A Toyoda Japan as Breaker drawing

2) RSBD 30 and RSBD 30C as Finisher Drawing

d) Combing Section.

In this section, 20% excessive waste (comber noil) is extracted. In this process, latest machinery Reiter E 62 (Swiss) is used which is very high quality performance machine.

e) Simplex Section.

In simplex section, sliver is fed and roving is produced. Finisher sliver is drafted and very low twist is inserted to form Roving. Roving is final preparatory shape of yarn in Back process stage, which will be converted into yarn in ring department.

Yarn Production Process

Ring is process where yarn is manufactured with clear specification of count and other specifications after Roving is creeled on ring machine from Simplex department. This roving is drafted and twisted to form yarn.

We are one of the leading, renowned and recognized Textile Group from 1986 with a vision to create goodwill and a brand image for our company ,our products and our country through establishing long term partnerships with suppliers and customers and in textile industry make our presence felt useful in all parts of the globe by conducting business within the framework of ethical business values and on our core business of textiles. We however will be ready to take upon all calling opportunities in international trade.Read More

We are one of the leading, renowned and recognized Textile Group from 1986 with a vision to create goodwill and a brand image for our company ,our products and our country through establishing long term partnerships with suppliers and customers and in textile industry make our presence felt useful in all parts of the globe by conducting business within the framework of ethical business values and on our core business of textiles. We however will be ready to take upon all calling opportunities in international trade.Read More

We have made a vigorous commitment to maintain an environment in which innovation flourishes throughout our units in performing all functions. Consistency in implementation of Hussain Group policies in context of Mission Statement and innovations through new products and technologies has a tremendous impact on our growth. Our growth and progress require innovation in everything we do. We try our best and to be careful not to miss any opportunity.

We have made a vigorous commitment to maintain an environment in which innovation flourishes throughout our units in performing all functions. Consistency in implementation of Hussain Group policies in context of Mission Statement and innovations through new products and technologies has a tremendous impact on our growth. Our growth and progress require innovation in everything we do. We try our best and to be careful not to miss any opportunity.

Read More

The Hussain Group considers that the most important contribution it can make to the social and material progress of the city of Multan is in performing its primary activities as efficiently as possible. It will thereby endeavour to promote the economy of the city of Multan by developing of its business, where appropriate and feasible. In addition, the Hussain Group recognises its responsibility to take a constructive interest in societal matters which may relate to welfare of people of society.Read More

The Hussain Group considers that the most important contribution it can make to the social and material progress of the city of Multan is in performing its primary activities as efficiently as possible. It will thereby endeavour to promote the economy of the city of Multan by developing of its business, where appropriate and feasible. In addition, the Hussain Group recognises its responsibility to take a constructive interest in societal matters which may relate to welfare of people of society.Read More

Dear Customer,

Dear Customer,

We, Hussain Mills Limited has continuously developed ourselves over the years and tailored successfully to a rapidly changing business environment. It has detained numerous opportunities along the way and is ready to do it again without losing sight of strategic goals, balanced product mix, careful risk management, and effective cost control measures.

Read More

We are one of the leading, renowned and recognized Textile Group from 1986 with a vision to create goodwill and a brand image for our company, our products and our country through establishing long term partnerships with suppliers and customers and in textile industry make our presence felt useful in all parts of the globe by conducting business within the framework of ethical business values and on our core business of textiles.We however will be ready to take upon all calling opportunities in international trade.Read More

We are one of the leading, renowned and recognized Textile Group from 1986 with a vision to create goodwill and a brand image for our company, our products and our country through establishing long term partnerships with suppliers and customers and in textile industry make our presence felt useful in all parts of the globe by conducting business within the framework of ethical business values and on our core business of textiles.We however will be ready to take upon all calling opportunities in international trade.Read More

-

Our History

-

Our Growth

-

Social Responsibility

-

Director's Message

-

Our Services

Our infrastructure

- Unit 1

- Unit 2

- Unit 3

- Unit 4

- Unit 5

- Unit 6

Hussain Mills Limited (Spinning Unit-1)

The Unit is located in the heart of Multan City at Fazalabad, Vehari Road, Multan. The strength of this unit is the results of a highly professional working atmosphere and dedicated group of executives who are efficiently managing the operations of the project..Read More

Hussain Mills Limited (Spinning Unit-2)

HML Unit-2 was established in year 2001 to join Hussain Group with an investment of Rs.500 million. This unit is situated at 35-kilometer Bahawalpur Road , Fatima Nagar Multan. Now this unit is producing best quality of knitting & weaving, carded & combed yarn..Read More

Hussain Mills Limited (Spinning Unit-3)

It was established in 2004 located at Fazal Abad Multan with latest machinery setup. This unit is specially designed to cater fancy yarn market with 14,448 spindles. Since the unit started its production, it is producing 100% contamination free yarn in all type of qualities including stretch yarn, slub yarn, multicounts etc.Read More

Hussain Mills Limited(Weaving Unit-4)

This beautiful unit joined Hussain Group in 2007, situated at 25 KM from Multan City near Qadir Pur Rawan. Our products have spread in all famous textile countries i.e. Germany, Holland, Italy, Portugal, France, China, Hong Kong, India, Sri Lanka, Turkey & USA.Read More

Hussain Mills Limited(Spinning Unit-5)

This is the latest spinning unit introduced by Hussain Group in 2005, located at 16.5 KM, Kabir Wala Bypass Khanewal. It is also a course count based unit having huge capacity of producing 800 .Read More